Faustovirus Capping Enzyme

Product information| Code | Name | Size | Quantity | Price | |

|---|---|---|---|---|---|

M2081S |

Faustovirus Capping Enzyme |

500 units ( 25000 units/ml ) | - | Unavailable in your region | |

M2081L |

Faustovirus Capping Enzyme |

2500 units ( 25000 units/ml ) | - | Unavailable in your region |

Faustovirus Capping Enzyme

GMP-grade reagent also available. Learn more.

Catalog #M2081

Product Introduction

- Faustovirus Capping Enzyme adds the m7G-cap (Cap-0) to the 5′ end of triphosphorylated and diphosphorylated RNA

- Experience improved capping efficiency, even on difficult substrates

- Achieve robust capping with less enzyme

- Set up reactions under a broad temperature range, for added flexibility

- Choose as an alternative to Vaccinia Capping System, with minimal optimization required

- Enable one-pot Cap-1 synthesis, as FCE is compatible with mRNA Cap 2′-O-Methyltransferase

- Benefit from no licensing fees from NEB for the use of FCE

- Getting ready to scale up RNA synthesis? Download our new technical note “Scaling of High-Yield In vitro Transcription Reactions for Linear Increase of RNA Production” for a generalized set of recommendations for synthesizing high yields of RNA.

- Product Information

- Protocols, Manuals & Usage

- FAQs & Troubleshooting

- Citations & Technical Literature

- Quality, Safety & Legal

Product Information

Description

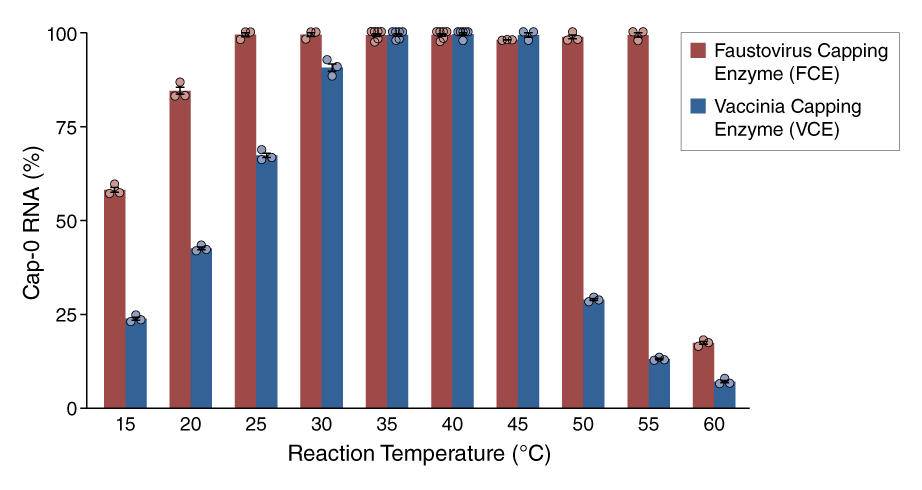

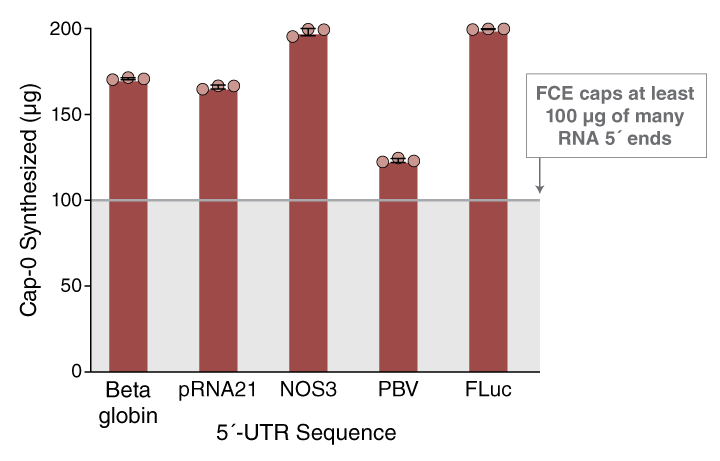

Faustovirus Capping Enzyme (FCE) catalyzes the addition of N7-methylguanosine cap (m7G) to the 5´ end of triphosphorylated and diphosphorylated transcripts, producing Cap-0 RNA. FCE is a single-subunit enzyme that combines the three activities necessary to produce the Cap-0 structure- triphosphatase, guanylyltransferase, and (guanine-N7)-methyltransferase. Installation of Cap-0 is a key step in eukaryotic mRNA maturation along with 2´-O-methylation at position 1 (Cap-1) and polyadenosine (poly(A)) tailing. The Cap-0 structure also promotes RNA stability and prevents inadvertent activation of innate immune responses triggered by triphosphorylated RNA.FCE retains significant capping activity at low temperatures and tolerates reaction temperatures up to 55°C. In many cases, 1 µl of FCE (25 units) can cap over 100 µg of RNA in 1 hour at 37°C. GTP and S-adenosylmethionine (SAM) are required for capping activity and are included with the enzyme.

Source: An E. coli strain that carries a plasmid encoding the Faustovirus Capping Enzyme with a C-terminal His-tag.

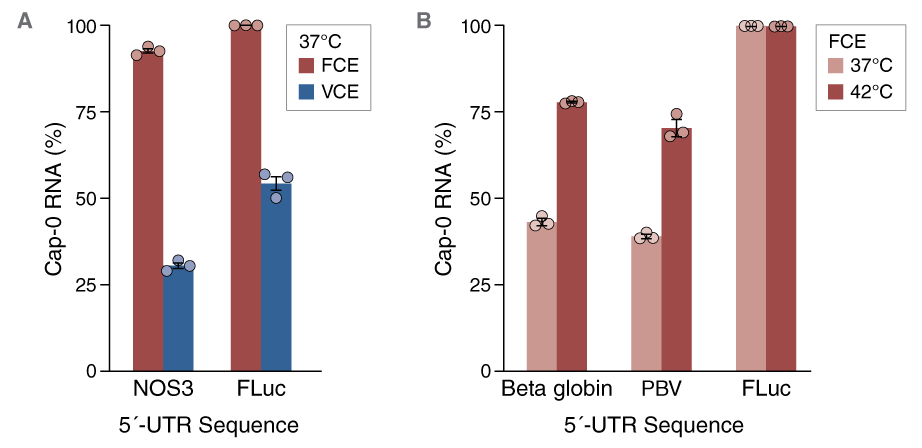

B. mRNA capping by FCE at 37°C and 42°C. 200 μg (~350 picomoles, 7 μM) of a 1.77 kb FLuc transcript having 5′-UTR sequences as indicated were treated with a limiting amount (25 units, 1 picomole or 20 nM) of FCE for 1 hour at 37°C or 42°C. Note that this is less than our recommended amount of enzyme highlighting the potential benefits of workflow optimization. All capping reactions were performed in 50 μl reactions containing 0.1 mM SAM, and 0.5 mM GTP, 1X FCE Capping Buffer for FCE reactions or 1X Capping Buffer for VCE reactions. Following capping reactions, mRNA capping was measured using targeted RNase H cleavage and LC-MS.

- This product is related to the following categories:

- RNA Capping,

Reagents Supplied

Reagents Supplied

The following reagents are supplied with this product:

| NEB # | Component Name | Component # | Stored at (°C) | Amount | Concentration | |||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||

Properties & Usage

Unit Definition

One unit of Faustovirus Capping Enzyme is defined as the amount of enzyme required to convert 75 pmol of a 20-mer ppp-RNA to Cap-0 RNA in 30 minutes at 37°C.Reaction Conditions

1X Capping Buffer

Supplement with 0.5 mM GTP and 0.1 mM S-adenosylmethionine (SAM)

Incubate at 37°C

1X Capping Buffer

50 mM Tris-HCl

5 mM KCl

1 mM MgCl2

1 mM DTT

(pH 8 @ 25°C)

Heat Inactivation

70°C for 10 minutesAddition of EDTA to 5 mM is recommended to avoid RNA hydrolysis.

Features

- Experience improved capping efficiency, even on difficult substrates

- Achieve robust capping with less enzyme

- Set up reactions under a broad temperature range, for added flexibility

Related Products

Companion Products

References

- Ramanathan, A. et al. (2016). Nucleic Acids Res . 44 (16), 7511–7526.

- Furuichi, Y., LaFiandra, A. & Shatkin, A. (1977). Nature. 266, 235-239.

- Schlee, M., Hartmann, G. (2016). Nat Rev Immunol . 16, 568-580.

Protocols, Manuals & Usage

Protocols

Application Notes

FAQs & Troubleshooting

FAQs

- What are Cap-0 and Cap-1?

- Can Faustovirus Capping Enzyme (NEB #M2081) use cap analogs in a capping reaction?

- Can Faustovirus Capping Enzyme (NEB #M2081) use GTP analogs in a capping reaction?

- Is Faustovirus Capping Enzyme sensitive to secondary structure?

- Is Faustovirus Capping Enzyme active at temperatures other than 37°C?

Citations & Technical Literature

Citations

Quality, Safety & Legal

Quality Assurance Statement

Quality Control tests are performed on each new lot of NEB product to meet the specifications designated for it. Specifications and individual lot data from the tests that are performed for this particular product can be found and downloaded on the Product Specification Sheet, Certificate of Analysis, data card or product manual. Further information regarding NEB product quality can be found here.Specifications

The Specification sheet is a document that includes the storage temperature, shelf life and the specifications designated for the product. The following file naming structure is used to name these document files: [Product Number]_[Size]_[Version]Certificate Of Analysis

The Certificate of Analysis (COA) is a signed document that includes the storage temperature, expiration date and quality controls for an individual lot. The following file naming structure is used to name these document files: [Product Number]_[Size]_[Version]_[Lot Number]- M2081L_v1_10160699

- M2081S_v1_10160698

- M2081L_v1_10164285

- M2081S_v1_10164284

- M2081L_v1_10185134

- M2081S_v1_10185135

- M2081L_v1_10185380

- M2081L_v1_10189866

- M2081L_v1_10206086

- M2081L_v1_10216765

- M2081S_v1_10216764

- M2081L_v1_10230206

- M2081L_v1_10238194

- M2081S_v1_10235973

- M2081S_v1_10251727

- M2081L_v1_10264780

- M2081S_v2_10264781

- M2081L_v2_10283190

- M2081S_v2_10293075

- M2081L_v2_10293720

Safety DataSheets

The following is a list of Safety Data Sheet (SDS) that apply to this product to help you use it safely.Faustovirus Capping Enzyme

Capping Buffer

S-adenosylmethionine (SAM)

GTP

Legal and Disclaimers

Products and content are covered by one or more patents, trademarks and/or copyrights owned or controlled by New England Biolabs, Inc (NEB). The use of trademark symbols does not necessarily indicate that the name is trademarked in the country where it is being read; it indicates where the content was originally developed. The use of this product may require the buyer to obtain additional third-party intellectual property rights for certain applications. For more information, please email busdev@neb.com.This product is intended for research purposes only. This product is not intended to be used for therapeutic or diagnostic purposes in humans or animals.

New England Biolabs (NEB) is committed to practicing ethical science – we believe it is our job as researchers to ask the important questions that when answered will help preserve our quality of life and the world that we live in. However, this research should always be done in safe and ethical manner. Learn more.

Licenses

"GMP-grade" is a branding term NEB uses to describe reagents manufactured at NEB’s Rowley facility. The Rowley facility was designed to manufacture reagents under more rigorous infrastructure and process controls to achieve more stringent product specifications and customer requirements. Reagents manufactured at NEB’s Rowley facility are manufactured in compliance with ISO 9001 and ISO 13485 quality management system standards. However, at this time, NEB does not manufacture or sell products known as Active Pharmaceutical Ingredients (APIs), nor does NEB manufacture its products in compliance with all of the Current Good Manufacturing Practice regulations.The supporting documents available for this product can be downloaded below.